E-Mail:sales@whalescnc.com

E-Mail:sales@whalescnc.com

Leading CNC Gantry machining center in CHINA

If you are looking for a Gantry Machining Centers or CNC machine manufacturer,GET A FREE QUOTE, NOW!!!

We are the most professional machine tool manufacturer of gantry machining centers in China. With more than 20 years of production experience, we can provide you with the highest quality gantry milling machines and the most satisfactory service.

Request a Quote

Processing Sample

Spiral Bevel Gear

Construction Machinery

Large Castings

Construction Machinery

Structural Parts

Aerospace Industry

Adapter Plate

Aerospace Industry

Strict Quality Management

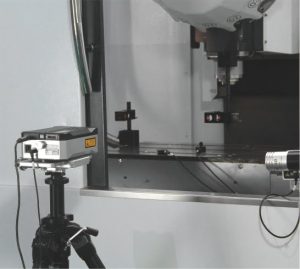

Laser interferometer testing

Rigorously checks machine tool accuracy and applies dynamic compensation for optimal and consistent positioning.

Circularity Detector

And with CNC system servo optimization, it ensures the overall linear and vertical accuracy of the machine.

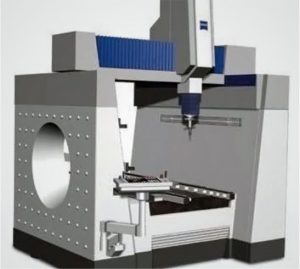

3 Coordinate Detection

The accuracy of key components is measured by high-precision three-coordinate

Processable Materials

US | EU | RU | JP |

6061 | AlMg1SiCu | 6061 | A6061 |

7075 | AlZn5.5MgCu | В95 | A7075 |

2024 | AlCu4Mg1 | Д16 | A2024 |

5052 | AlMg2.5 | АМг2,5 | A5052 |

US | EU | RU | JP |

304 | X5CrNi18-10 | 08Х18Н10 | SUS304 |

316 | X5CrNiMo17-12-2 | 08Х17Н13М2Т | SUS316 |

410 | X12Cr13 | 12Х13 | SUS410 |

US | EU | RU | JP |

4140 | 42CrMo4 | 38ХМ | SCM440 |

4130 | 25CrMo4 | 30ХМА | SCM430 |

US | EU | RU | JP |

D2 | X153CrMoV12 | Х12МФ | SKD11 |

O1 | 1.251 | 9ХС | SKS3 |

US | EU | RU | JP |

C11000 | Cu-ETP | М1 | C1100 |

C12200 | Cu-DHP | М2 | C1220 |

US | EU | RU | JP |

C28000 | CuZn37 | Л63 | C2801 |

C37700 | CuZn39Pb2 | ЛС59-1 | C3771 |

US | EU | RU | JP |

Grade 5 | Ti6Al4V | ВТ6 | TA6V |

Grade 2 | Ti40 | ВТ1-0 | TA2 |

What is a Gantry machining center?

A Gantry machining center operates on the principle of computer numerical control (CNC) to execute complex milling, drilling, and cutting tasks. The machine’s dual column structure provides a stable platform, allowing the spindle to move along the X, Y, and Z axes with unparalleled precision. This ensures that the cutting tool interacts with the workpiece exactly as programmed, delivering high-quality results every time.

- Robust Gantry Structure: Minimizes vibrations and maximizes rigidity for intricate operations.

- High-Speed Operations: Engineered for tasks requiring quick, precise movements.

- Versatility: Capable of handling a wide range of materials and complex geometries.

What Makes a Good Gantry machining center?

When it comes to selecting a Gantry machining center, there are five critical factors to consider. First and foremost is stability; our machines boast a robust structure capable of withstanding heavy loads, ensuring that your operations run smoothly. Next is precision, achieved through high-accuracy guide rails and spindles that guarantee exact cuts and measurements. Speed is another vital aspect; our machining centers are engineered for high-speed processing, allowing you to complete tasks efficiently without compromising on quality. Ease of use is also a priority, featuring user-friendly controls and software that make complex tasks manageable. Lastly, we offer reliable after-sales support, including a comprehensive warranty and dedicated customer service, to ensure that you’re never left in the lurch.

Roller Guide Rails

Enhances load-bearing capacity and improves positioning accuracy and rigidity for heavy-duty tasks.

Variable Speed Gearbox

High-horsepower, 4500-6000 rpm spindle motor with a two-stage gearbox for both heavy and precision cutting.

Stepped Cross Beam

Provides tiered support for enhanced rigidity and stability, optimizing load distribution during complex machining tasks.

Variable Speed Gearbox

High-horsepower, 4500-6000 rpm spindle motor with a two-stage gearbox for both heavy and precision cutting.

Why Choose WhalesCNC GMC Series?

- Heavy-Duty Roller Linear Guide Rails: High precision in the X/Y axis.

- Ultra-Wide Square Guide Rails: Strong earthquake resistance in the Z-axis.

- Hydraulic and Nitrogen Double Counterweights: Stability during high-speed vertical movements.

- Automated Waste Management: Double spiral and chain chip conveyors.

- Customizable Door Width: Various options to meet your processing needs.

Confused about specifications?

You can upload drawings of machined parts. Our experts will help you determine the best machine for your needs.