E-Mail:sales@whalescnc.com

E-Mail:sales@whalescnc.com

11 Common CNC Calculation Formulas

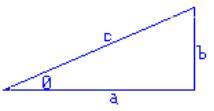

1. Trigonometric Functions Calculation

- tanθ = b/a, θ = tan^-1 b/a

- Sinθ = b/c, Cos = a/c

2. Cutting Speed Calculation

- Vc = (π * D * S) / 1000

- Vc: Cutting speed (m/min)

- π: Pi (3.14159)

- D: Tool diameter (mm)

- S: RPM (rotations per minute)

Example: Using a Φ25 cutter, Vc is 25 m/min, find S?

- S = 1000 * 25 / π * 25

- S = 320rpm

3. Feed Rate (F Value) Calculation

- F = S * Z * Fz

- F: Feed rate (mm/min)

- S: RPM

- Z: Number of teeth

- Fz: Actual feed per tooth (mm)

Example: A standard 2-tooth vertical milling cutter cuts at 2000rpm, what is the feed rate (F value)?

- F = 2000 * 2 * 0.25

- F = 1000 (mm/min)

4. Scallop Height Calculation

- Scallop = (ae * ae) / 8R

- Scallop: Scallop height (mm)

- ae: XY pitch (mm)

- R: Tool radius (mm)

Example: Φ20R10, target scallop height is 0.002mm, what is the Pitch?

- ae = 0.4mm

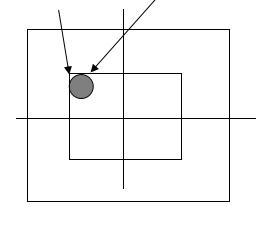

5. Chip Escape Hole Calculation

- Φ = √2 * R^2, X, Y = D / 4

- Φ: Chip escape hole diameter (mm)

- R: Tool radius (mm)

- D: Tool diameter (mm)

Example: Known milling cutter is ψ10; what is the minimum escape hole diameter? Center coordinates?

- Φ = 7.1(mm)

- X, Y = 2.5 mm

- Center coordinates are (2.5, -2.5)

6. Material Removal Rate Calculation

- Q = (ae * ap * F) / 1000

- Q: Material removal rate (cm^3/min)

- ae: XY pitch (mm)

- ap: Z pitch (mm)

Example: Known mold needs cavity contouring, Φ35R5 cutter XY pitch is 60% of the tool, each layer cuts 1.5mm, feed rate is 2000mm/min, what is the material removal rate?

- Q = 63 cm^3/min

7. Feed per Tooth Calculation

- Fz = hm * √(D / ap)

- Fz: Actual feed per tooth

- hm: Theoretical feed per tooth

- ap: Z pitch (mm)

- D: Cutter diameter (mm)

Example: depo Φ35R5 cutter, cutting NAK80 material, hm is 0.15mm, Z-axis cutting depth is 1.5mm, what is the feed per tooth?

- Fz = 0.5mm

8. Die Edge Machining Method

- Cutting depth = Sheet thickness – Edge height + Drill tip (0.3D)

- D represents the diameter of the tool

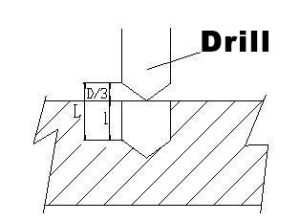

9. Drilling Time Formula

- T(min) = L(min) / N(rpm) * f(mm/rev)

- = πDL / 1000vf

- L: Total length of the hole

- N: Number of rotations

- f: Feed rate coefficient

- D: Diameter of the drill bit

- v: Cutting speed

Example: Hole depth l, total length of the hole L, then L = l + D/3

- T = L / Nf = πDL / 1000vf

10. Feed Rate Coefficient Table (f)

| Diameter (mm) | Feed (mm/rev) |

|---|---|

| 1.6~3.2 | 0.025~0.075 |

| 3.2~6.4 | 0.05~0.15 |

| 6.4~12.8 | 0.10~0.25 |

| 12.8~25 | 0.175~0.375 |

| Above 25 | 0.376~0.625 |

- 1 inch = 25.4 mm = 8 parts

- 25.4 / number of teeth = pitch

Example: 25.4 / 18 = 1.414, the pitch is 5/16 thread

11. Horsepower (Gun Drill)

- W = Md * N / 97.410

- W: Required power (KW)

- Md: Torque (kg-cm)

- N: Number of rotations (rpm)

Torque Calculation Formula:

- Md = 1 / 20 * f * ps *

- f: Feed rate coefficient (mm/rev)

- r: Radius of the drill bit (mm)

- α: Cutting resistance ratio ps. For small feeds, general steel is 500 kg/m²; general cast iron is 300 kg/m²

Need to buy a machine tool?

You can upload drawings of machined parts. Our experts will help you determine the best machine for your needs.

About WhalesCNC

WhalesCNC is a high-quality CNC machine tool manufacturer located in Xuzhou, Jiangsu, China. It has more than 20 years of manufacturing experience and is committed to comprehensive solutions to improve cutting efficiency.