E-Mail:sales@whalescnc.com

E-Mail:sales@whalescnc.com

Difference Between 3Axis, 4Axis, And 5Axis CNC Milling Machine

Introduction

What is CNC Milling?

CNC milling is a computer-controlled process used to cut, shape, and assemble materials like metal, plastic, and wood. It’s a cornerstone in manufacturing, offering precision and complexity in part creation.

Why Choosing the Right Machine Matters

The type of CNC machine you select can make or break your project. It affects your work’s speed, cost, and quality. Knowing the differences between 3-Axis, 4-Axis, and 5-Axis machines is crucial for optimal results.

What You’ll Learn in This Article

This article cuts to the chase, explaining the key differences between 3-Axis, 4-Axis, and 5-Axis CNC milling machines. You’ll learn their basic functions, pros, cons, and how to make an informed choice for your specific needs.

3-Axis Machines

Basics and Applications

3-Axis CNC milling machines operate on the X, Y, and Z axes. These machines are the most straightforward type of CNC milling machines and are usually the first choice for simple milling tasks. They’re commonly used for drilling holes, cutting slots, and basic engraving.

Pros and Cons

Pros:

- Cost-Effective: Generally less expensive than their 4-Axis and 5-Axis counterparts.

- Ease of Use: Simpler to operate, making them ideal for beginners or less complex projects.

- Availability: Widely available and supported, with a broad range of compatible tools.

Cons:

- Limited Complexity: Can’t handle as many complex tasks as 4-Axis or 5-Axis machines.

- Multiple Setups: For more complex parts, multiple setups may be required, increasing production time.

4-Axis Machines

Basics and Applications

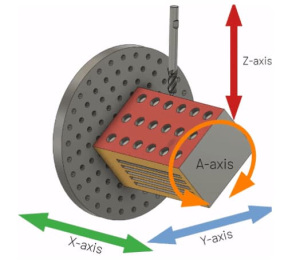

4-Axis CNC milling machines add a rotary axis to the standard 3-Axis machines, usually rotating around the X-axis. This added axis allows for more complex shapes and angles to be machined without repositioning the workpiece. Typical applications include engraving curved surfaces and machining cylindrical parts.

Pros and Cons

Pros:

- Increased Complexity: Capable of handling more complex geometries than 3-Axis machines.

- Reduced Setups: The added axis minimizes the need for multiple setups, saving time.

- Versatility: Suitable for a broader range of applications, including Auto Tool Changer functionalities.

Cons:

- Cost: Generally more expensive to purchase and operate than 3-Axis machines.

- Learning Curve: Requires more expertise to operate effectively.

5-Axis Machines

Basics and Applications

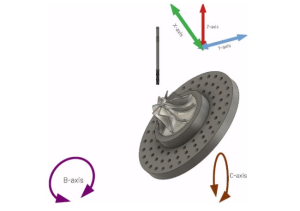

5-Axis CNC milling machines offer the highest level of complexity and flexibility in CNC machining. These machines operate on the X, Y, Z, A, and B axes, allowing for simultaneous movement and intricate machining. They are commonly used in industries like aerospace for creating complex components and in automotive manufacturing for precision parts.

Pros and Cons

Pros:

- High Complexity: Can create extremely complex shapes and intricate designs.

- Time Efficiency: Reduced need for multiple setups speeds up production.

- Advanced Features: Often come with specialized features like a CNC Tool Magazine for tool management.

Cons:

- Cost: High initial investment and operational costs.

- Expertise Required: Demands a high level of skill and experience to operate.

Quick Comparison

Here’s a quick table comparing the key features, pros, and cons of 3-Axis, 4-Axis, and 5-Axis CNC milling machines:

| Feature/Aspect | 3-Axis Machines | 4-Axis Machines | 5-Axis Machines |

| Axes | X, Y, Z | X, Y, Z, A | X, Y, Z, A, B |

| Complexity | Low | Medium | High |

| Cost | $ | $$ | $$$ |

| Ease of Use | High | Moderate | Low |

| Applications | Drilling, Cutting | Engraving, Cylindrical Parts | Complex Components |

| Pros | Cost-effective, Easy to use | Increased complexity, Reduced setups | High complexity, Time-efficient |

| Cons | Limited complexity, Multiple setups | Higher cost, Learning curve | High cost, Expertise required |

Choosing the Right Machine

Key Factors to Consider

When it comes to selecting the right CNC milling machine for your project, several factors come into play. Here are some key considerations:

Complexity of the Project

- 3-Axis: Suitable for simpler projects with less intricate designs.

- 4-Axis: Ideal for projects that require a moderate level of complexity.

- 5-Axis: Best for highly complex projects with intricate geometries.

Budget Constraints

- 3-Axis: Most cost-effective, but may require multiple setups for complex parts.

- 4-Axis: A balanced option in terms of cost and capabilities.

- 5-Axis: High initial and operational costs.

Skill Level

- 3-Axis: Easier to operate, ideal for beginners.

- 4-Axis: Requires some experience and expertise.

- 5-Axis: Demands a high level of skill and training.

Time Constraints

- 3-Axis: May require more time due to multiple setups.

- 4-Axis: Saves time by reducing the need for repositioning.

- 5-Axis: Most time-efficient but requires expertise for optimal utilization.

By carefully evaluating these factors, you can make an informed decision that aligns with your project’s specific needs and constraints.

Conclusion

Summary and Final Thoughts

Choosing the right CNC milling machine is a critical decision that can significantly impact the success of your project. Whether it’s a 3-Axis, 4-Axis, or 5-Axis machine, each comes with its own set of capabilities, pros, and cons.

- 3-Axis Machines: Best for simple tasks and are the most cost-effective.

- 4-Axis Machines: Offer a balance between complexity and cost, suitable for a wider range of applications.

- 5-Axis Machines: Provide the highest level of complexity but come at a premium price.

The key to making the right choice lies in understanding your project’s specific needs, your budget, and your skill level. By taking these factors into account, you can select a machine that not only meets your requirements but also maximizes efficiency and output.

Thank you for reading this guide. We hope it has provided you with valuable insights to help you make an informed decision in choosing the right CNC milling machine for your needs.

Get a Customized Quote Today!

If you’re still unsure about which CNC milling machine is the perfect fit for your project, we’re here to help! Our team of experts can provide you with a customized quote tailored to your specific needs and budget.

Why Choose Us?

- Over 20 years of experience in the field of milling.

- A dedicated team of engineers and professionals.

- Committed to delivering quality, coordination, and the best service.

Don’t leave your project to chance. Contact us today for a no-obligation quote and take the first step towards achieving optimal results.

Need to buy a machine tool?

You can upload drawings of machined parts. Our experts will help you determine the best machine for your needs.

About WhalesCNC

WhalesCNC is a high-quality CNC machine tool manufacturer located in Xuzhou, Jiangsu, China. It has more than 20 years of manufacturing experience and is committed to comprehensive solutions to improve cutting efficiency.